The Amazing Hydraulic Ram Pump

(Note: These days, industrial catalogs list a ram pump as a piston pump actuated by a hydraulic cylinder. Kids! These are often used for pumping pulp slurry in paper mills. That isn't what this page is about.)

Once upon a time, there was an English plumber. He was having a heck of a time with a lead pipe in an English hospital. (Lead pipe? This was hundreds of years ago and they didn't know any better!) Anyway, the pipe frequently broke when someone turned the tap off quickly. The water was coming from a cistern, so there really wasn't much pressure. The pipe kept breaking.

This was looking bad for his reputation, so the plumber determined himself to relieve this excess pressure. To do so, he ran a pipe from the faucet up the outside wall, until it was above the level of the cistern. Problem solved! NOW, however, every time the faucet was turned off, a jet of water shot up the outside wall. It didn't hurt anything, but it wasted water. The plumber extended the pipe higher, but the water still shot out. He got the bright idea of directing this jet of water into a small tank on the top floor of the hospital. Then, the upper floor had a supply of running water!

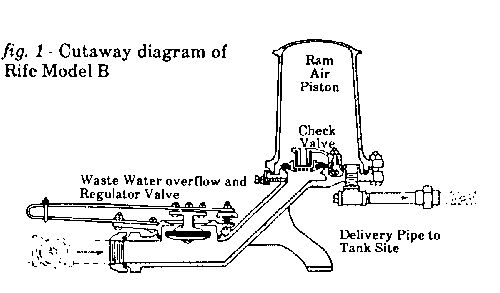

Fig. 1. We use a Rife Model 20, similar to the one above.

There is none better.

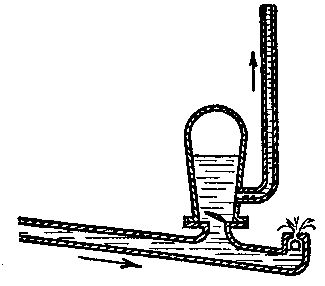

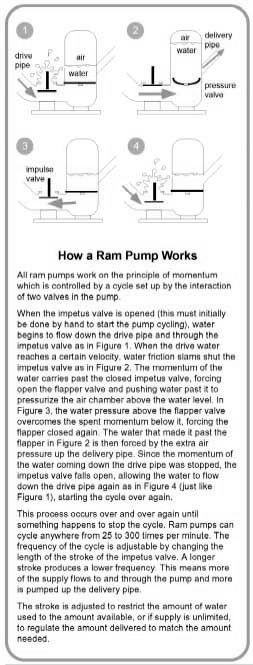

Somewhere along the line, a Frenchman named Montgolfier (He and his brother were best known for being the first to send livestock aloft in a hot air balloon. It takes all kinds...) rigged up a couple of valves to automate the process. As flow developed, it would slam a ball against a seat, forcing the pressure through a check valve and into an air chamber. It looked like this:

Fig. 2. Montgolfier's Water Ram

Okay, we spoke of high pressure breaking the pipe? From where did this pressure come? Let's say the level of the cistern is 16 feet above the level of the faucet. Figure about .5 psi for every foot of elevation. 7-8 pounds won't break a pipe, yet you've probably heard pipes bang when a faucet closes quickly. What's causing this?

Now, I'll get out Mark's Standard Handbook for Mechanical Engineers. They have a simpler formula than the one we posted earlier. If we ignore little things like the temperature of the water and the elasticity of the pipe, we'll save a lot of math and not give up much in accuracy. Besides, we want to see just how much damage we can do. The handbook gives the stripped down equation of DeltaP = -P x c x DeltaV. DeltaP will be our change in pressure. P is the inlet pressure (let's say 8). c is the velocity of sound in water, or 4860 (this sonic shockwave is the secret source of the big numbers). DeltaV is the change in velocity of the water (let's say we go from 3 feet/second to zip, for -3). Our DeltaP = -8 * 4860 * -3 = 116640. Don't panic, we need to divide that by 144 to get pounds per square inch. Wow! That's still 810 psi! No wonder the pipes broke! Mark's editor concludes "Water hammer can be dangerous."

Turning the valve off slowly, having an air

chamber, or having pipes made of rubber would have reduced this pressure

surge to manageable, or even useful levels.

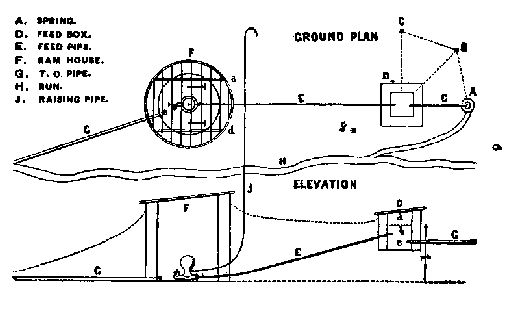

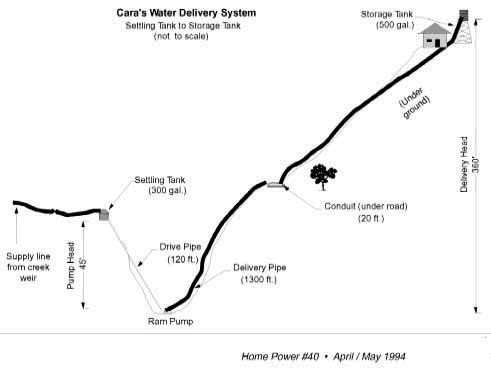

Fig. 3. This is how you lay it out.

For a more practical example, water from my spring runs down the hill in a 2 inch pipe to a standpipe. The water level in the standpipe is 10 feet. From there, it goes down a 60' 2 inch drive pipe to the ram. Anybody want to do the math? It bangs away about 80 times per minute. The pump pushes the water through the 3500 feet of pipe to my house and barn. The highest point is around 85 feet above the pump. Rather than build an elevated tower, I have the water go into pressure tanks. There is less than a gallon per minute from the pump, but the pressure tanks allow us to flush toilets, shower and do laundry all at the same time. Most of the water ends up going out a relief valve that serves two purposes: It gives my cats and armadillos drinking water and it prevents my pipes from exploding. We've been using various rams since 1986 and that is our only source of water.

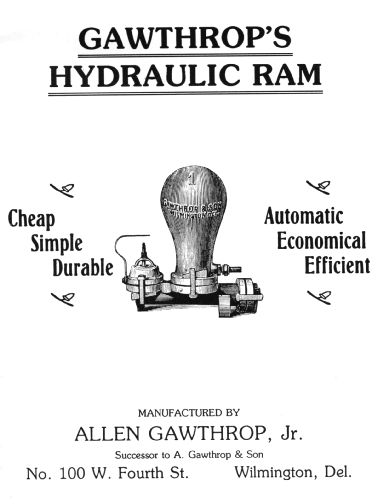

Fig. 4. It stands to figure that a cast iron machine that sits

in water will get some rust on it. Getting the bolts loose is often

best done with a torch. Gawthrop's pump was held together with wedges.

It was assembled and disassembled with a few taps of a hammer.

You know that expensive spring water everybody pays so much for? That's what I use to wash my car and flush my commode!

Fig. 5. Catalog cut of a pre-1919 Model. Newer ones use

a hinged valve instead of the hairpin spring. Newer models also use

a thick rubber disc over a grate for a check valve. Either way works

fine

--------------------------------------------------------------------

HOMEPOWER MAGAZINE is a wonderful resource. They have allowed us to use the pictures and diagrams below AND several articles in one Adobe Acrobat PDF file. If you have Acrobat Reader, go ahead and download this so you'll have it. If not, click the icon to get it. Please note that Acrobat's default setup does not always work right. If you have problems, read our HELP notice. Be sure to visit HP to download their latest issue and browse through their download section.

DOWNLOAD RAMPUMPS.PDF

(about 3 minutes)

Fig. 6. This Folk Ram looks like a solid performer. Read the

article.

Fig. 7. A real system from Homepower Magazine

Fig. 8. Courtesy Homepower Magazine

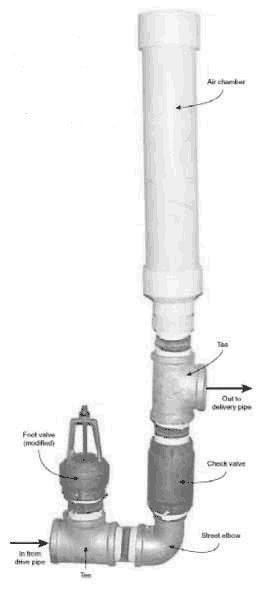

Fig. 9. We used a homebuilt pump similar to this,

but it had

a hairpin valve like the Model B Rife.

Easy to build and dependable. Get the download!

Page updated January 2005

Copyright 2005 by N. Collier, Publisher and others.